1. Introduction

Shrimp is the most economically valuable seafood commodity worldwide. During the period from 2022 to 2025, aquaculture and capture production reached nearly 10 million tons, making a significant contribution to global trade and food security. However, shrimp is rich in proteins, unsaturated fatty acids, and has high water activity, making it highly perishable and prone to quality deterioration if not properly preserved. Freezing is the primary method used to extend shelf life. Nevertheless, during freezing and thawing processes, shrimp still undergoes protein denaturation, lipid oxidation, moisture loss, and a decline in sensory quality.

Figure 1. Frozen shrimp treated with STPP

Therefore, food additives, particularly sodium tripolyphosphate (STPP), have been widely used to maintain the product’s weight and structural integrity (Durage, 2025).

2. Negative Effects of the Freezing Process

During freezing, water within muscle tissues forms large ice crystals that damage cellular structures. Upon thawing, the released water causes weight loss and makes the shrimp meat dry and tough. Denaturation of myofibrillar proteins reduces water-holding capacity, elasticity, and gel-forming ability.

Lipid oxidation also occurs—particularly affecting EPA and DHA—resulting in the formation of aldehydes and ketones that produce off-odors. In addition, the shrimp’s color becomes pale or dull due to the degradation of the astaxanthin pigment. These changes significantly affect the sensory quality and commercial value of shrimp.

3. Role of STPP

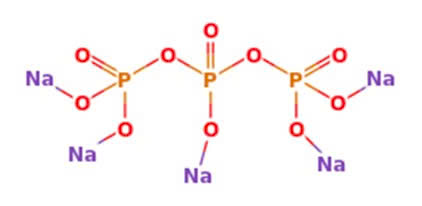

STPP is an inorganic phosphate additive capable of forming complexes with Ca²⁺ and Mg²⁺ ions, thereby stabilizing proteins and reducing the rate of oxidation. STPP also increases the pH of muscle tissue (up to 9–10), which causes muscle fibers to swell and creates more space for water retention.

Figure 2. Structural formula of Sodium Tripolyphosphate

When shrimp is treated with an STPP solution (typically 2–5% for 20–60 minutes), studies have shown a significant improvement in water-holding capacity, higher post-cooking yield, and softer, lighter-colored muscle texture. However, excessive use of STPP can cause artificial weight gain, result in a slimy texture, and leave phosphate residues that pose health risks (such as kidney and cardiovascular diseases) and environmental issues (eutrophication of water bodies). Therefore, many countries have established limits on STPP levels in seafood products (Xuan et al., 2025).

4. Alternatives to STPP

Due to growing health and environmental concerns, many studies have focused on developing alternatives to STPP:

- Alkaline compounds (NaHCO₃, Na₂CO₃, KOH): increase pH and improve water retention but may impart a soapy taste and promote microbial growth.

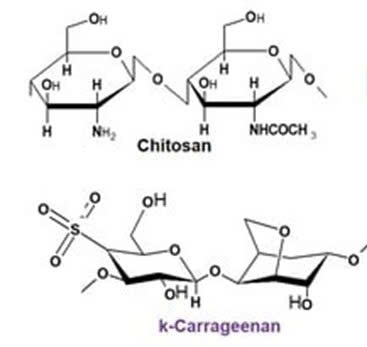

- Polysaccharides (chitosan, alginate, carrageenan, trehalose): form protective coatings, inhibit ice crystal formation, and reduce oxidation. Trehalose is particularly effective due to its small molecular size and high permeability.

Figure 3. Chitosan and Carrageenan Used as Edible Coatings

- Proteins and protein hydrolysates (gelatin hydrolysate, amino acids): possess antioxidant properties and help maintain muscle structure. These are naturally derived and align with the clean-label trend.

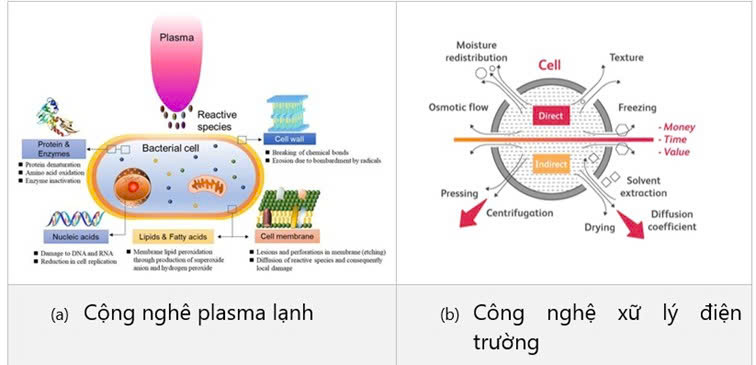

- Non-thermal technologies such as ultrasound, high-pressure processing (HPP), cold plasma, and pulsed electric fields (PEF): enhance product quality, inhibit microbial growth, and improve the efficiency of additive absorption. However, these technologies require high investment costs and further research for large-scale industrial application (Du et al., 2022).

Figure 4. Some Non-Thermal Technologies Used in Food Processing

5. Challenges and Limitations

The use of STPP and its alternative additives comes with certain limitations. For STPP, public health and environmental concerns are the primary issues. Although alternatives are generally safer, their effectiveness is inconsistent and depends on concentration, processing conditions, and the biological characteristics of each shrimp species. Additionally, production costs and consumer acceptance are key factors determining their industrial application.

6. Conclusions and Future Directions

STPP remains an effective preservative for frozen shrimp; however, sustainable development trends call for alternative solutions. Future research should focus on combining multiple natural additives, optimizing processing conditions, and applying non-thermal technologies to enhance effectiveness. Moreover, establishing clear, transparent regulations and clean-label standards will help meet modern consumer demands. Interdisciplinary research involving food technology, biochemistry, and environmental science is essential to develop shrimp preservation models that are effective, safe, and environmentally friendly.

References

1.Durage, T.T.D. (2025). Replacing Sodium Tripolyphosphate in Frozen Shrimp Preservation: Soaking Treatments, Nonthermal Technologies and Their Limitations. Journal of Food Science. doi.org/10.1111/1750-3841.70365.

2.Xuan, T.C., Nguyen, V.H., Tran, P.D. (2025). Optimization of sodium tripolyphosphate treatment conditions on the weight of giant freshwater prawns (Macrobrachium rosenbergii) during frozen processing. International Journal of Food Science and Technology. doi.org/10.1111/ijfs.16740.

3.Du, Q., Shen, Q., Sun, D. (2022). Low-temperature vacuum permeation of sodium tripolyphosphate and trehalose maintains the water-holding capacity of shrimp during frozen storage. Frontiers in Nutrition. doi.org/10.3389/fnut.2022.806521.