1. Context and Potential

Fruit peels are abundant sources of polysaccharides (especially pectin), natural pigments (betalains), polyphenols, and other bioactive components, making them highly suitable for value-creation routes in cosmetics, food, and packaging. At the systemic scale, fruits and vegetables account for approximately 45% of global food waste. Vietnam alone contributes about 51.1% of the world’s dragon fruit production, where processing generates 22–44% peel residues rich in pectin and betalains, an ideal basis for “green” value-added products.

On pectin raw materials: Pectin extracted from red dragon fruit (RDF) peels reached a yield of 19.8% with a degree of esterification (DE) of 28.09–56.80%, while pectin from durian rind (DR) achieved 23.5% with DE 30.4% (low-methoxyl), forming a “dual functionality” for different gelling/stabilizing systems.

2. Technological Routes

2.1. Recovery and Characterization of Materials

Sequential extraction from dragon fruit peel: Betalains are first recovered using 96% ethanol at 45 °C for 1 h. The residue is then subjected to pectin extraction with 1 M citric acid at 80 °C for 2 h, at a solid-to-liquid ratio of 1:40. Pectin is precipitated with ethanol and dried at 50 °C. This approach maximizes value from a single raw source while minimizing secondary waste.

Yield–DE and extraction conditions: At 1:40 for 90 min, pectin yield was 22.97%. Increasing citric acid concentration to 1 M boosted yield up to 57.26%, but reduced DE from 58.62% to 28.09%, requiring balance between economic feasibility and application standards.

Structural characteristics: DE was determined according to the Food Chemical Codex. FTIR spectra showed OH stretching at 3200–3400 cm⁻¹, CH at 2800–3000 cm⁻¹, a “fingerprint” region at 800–1200 cm⁻¹, –COO⁻ at 1630–1650 cm⁻¹, and –COOR at 1730–1760 cm⁻¹.

Cosmetic applications of multi-source pectin: The RDF–DR pair allows adjustment of viscosity, moisture retention, and emulsion stability in skincare formulations.

2.2. Stabilization and Encapsulation of Betalains

Freeze-drying with MCC: Encapsulation with microcrystalline cellulose (MCC) at BE:MCC = 1:5 produced betalain powders with 76.93 mg/g betacyanin. The powder exhibited strong antioxidant activity (IC₅₀ = 6.77 mg/mL) and stability within pH 3–7.

Effect of water activity (aw): After 7 days, betalain retention at aw = 0.089 was 93.8–97.1% (MCC at ratios 1:3–1:10), but dropped to 77–82% at aw = 0.898. Rice bran powder (RBP) encapsulates were less stable at high aw.

Maltodextrin–pectin blends: Previous reports indicated that malto:pectin systems at 1:3–1:1 improved color stability. With pigment-to-carrier ratios of 1:5, retention exceeded 80% under accelerated tests, suitable for food/cosmetic uses.

Pre-mix application: BE–MCC powders serve as colorants in films or cosmetic formulations, reducing degradation from heat, light, and oxygen compared to direct extracts.

3. Application Demonstrations

3.1. Vegan Cosmetics Based on Fruit Pectin

A lotion formulation (1.5% w/w pectin) combined betalains/retinol and Leuconostoc/Radish Root Ferment (antibacterial) at pH 4.0–4.5, viscosity < 500 cP, and uniform spreadability, ensuring safety for retinol-containing products.

Stability: At 27 °C, three RDF-pectin lotion bases remained gel-stable for 15 days (with slight discoloration). DR-pectin bases separated and discolored within 1–2 days. All formulas were stable at 4 °C. These results strengthen the direction of “vegan skincare” from fruit by-products, with RDF pectin providing structure/viscosity and BE–MCC as antioxidant/antibacterial actives.

3.2. Natural Colorants for Food and Cosmetics

Encapsulated betalains are stable at pH 3–7 (optimal around pH 5), suitable for beverages, gummies, lip balms, and blush powders. Pasteurization and 4 °C storage for 7 days showed negligible degradation. However, stability under 100 °C heating was poor, suggesting applications in “low-heat” products.

3.3. Freshness Indicator Films for Beef

Design: RDF pectin (from post-BE extraction residue) blended with PVA at ratios 5:5, 4:6, 3:7 (w/w), and color-activated with BE–MCC powder (0.02–0.08%).

Optical–mechanical–barrier properties: At 0.08% BE, films blocked UV effectively. The 4:6 pectin:PVA ratio had the lowest WVTR (2207 g/m²/day) and high elongation (66.4%), balancing moisture resistance and flexibility for active packaging.

Indicator mechanism and validation: Films shifted from red-pink to brown-yellow under pH changes or NH₃ vapor (1 M) within 120 min. During beef storage at 2–4 °C, the film color correlated with TVB-N increases after 6 days. Ammonia was quantified following TCVN 3706:1990.

Circular significance: The “sequential extraction” approach integrates pectin recovery after betalains, reducing waste and yielding two product streams (smart films and natural colorants) from one by-product source.

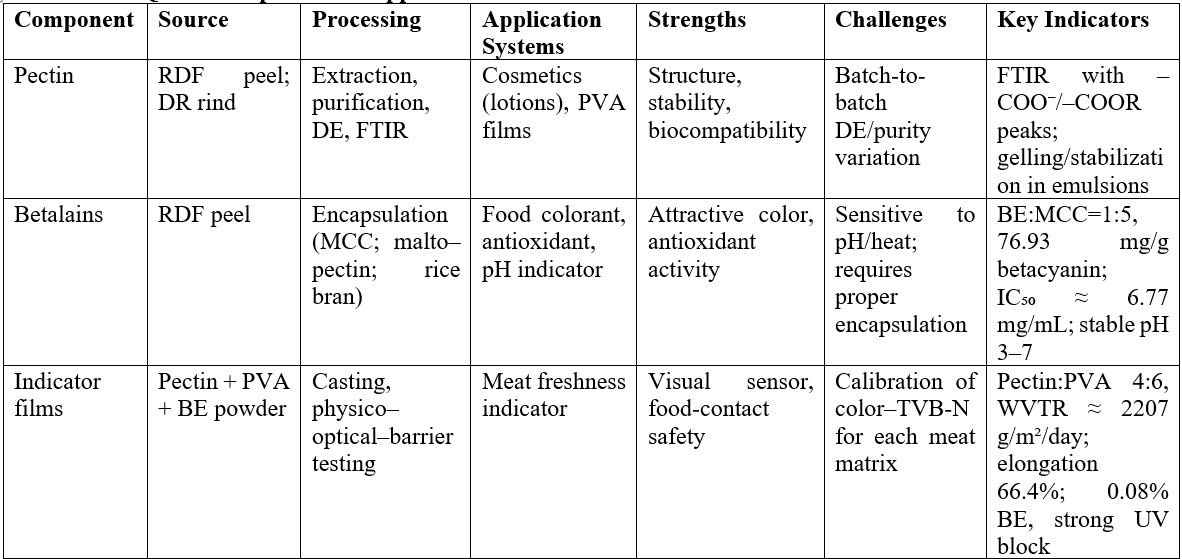

4. Quick Comparison of Application Routes

5. Deployment and Scale-Up Directions

Sequential valorization strategy: Prioritize betalain recovery, followed by pectin extraction, with application pathways split into pigments (food/cosmetics) and films (indicators). This maximizes value, shortens supply chains, and minimizes residual waste.

Quality standardization:

- Pectin: control DE, ash/heavy metals, viscosity; confirm FTIR characteristic ranges for reproducibility.

- Betalains (encapsulated): thermal–pH–light–storage stability profiles; core-to-wall ratio 1:5, freeze-dried; maintain aw ≤ 0.2 for >90% color retention during short storage.

- Indicator films: select Pectin:PVA 4:6 (low WVTR, flexible); load 0.06–0.08% BE for UV blocking and optimal background color.

Application blocks and validations:

- Cosmetics: evaluate pH/viscosity/spreadability/stability; add antibacterial/ antioxidant assays for RDF and DR pectin lotions; extend “vegan skincare” (blush, lipsticks).

- Food: confirm encapsulated betalain color stability in acid/sugar matrices (drinks, gummies), focusing on low-heat processes.

- Smart packaging: calibrate color–TVB-N response for beef at 2–4 °C (TVB-N rose from 6.52 to 38.2 mg/100 g after 5 days, exceeding the 20 mg/100 g limit per TCVN 12429-2:2020, with distinct color changes). Extend to pork/poultry/seafood with custom calibration curves. Suggested pilot (TRL 5–6): 3×3 cm film tags; establish color charts in NH₃ gas and pH 3–10 buffers; verify WVTR/mechanical durability of 4:6 films; digitize indicator via RGB-phone matching.

6. Conclusion

The presented workflow demonstrates a comprehensive valorization pathway for fruit by-products: recovery (pectin, betalains), stabilization (encapsulation), application (cosmetics, food pigments, TVB-N indicator films). This technology not only enhances economic value from agro-waste but also reduces environmental burden, laying the foundation for circular solutions in food–cosmetics–packaging. Future steps should include semi-industrial pilot trials, batch-level quality control, and long-term safety–performance validation under real-world conditions.

References

- Mang T.T.X., Dang-Bao T., Tran U.P.N. (2025). A Smart Indicator of Beef Spoilage Using Pectin and Betalains from Red Dragon Fruit Peels, Waste & Biomass Valorization.

- Huynh U.D.H. et al. (2024). Recovery of Beneficial Compounds from Fruit Waste for Application to Potential Skincare Products, Chemical Engineering Transactions, 113, 325–330.

- University-level Research Reports (03/2024 & 09/2022): Encapsulation of betalains (MCC/RBP), TVB-N indicator, and pilot parameters for extraction–encapsulation–film casting.

Tran Phuoc Nhat Uyen

Faculty of Engineering – Technology, Van Hien University