Food waste currently stands as one of the paramount challenges of our time, situated at the nexus of food security, resource sustainability, and climate change. In developed economies, the largest waste stream occurs at the consumption stage at the end of the food chain (restaurants, households). Traditional management via landfilling not only squanders land and water resources but also generates greenhouse gases and toxic leachate [1,2].

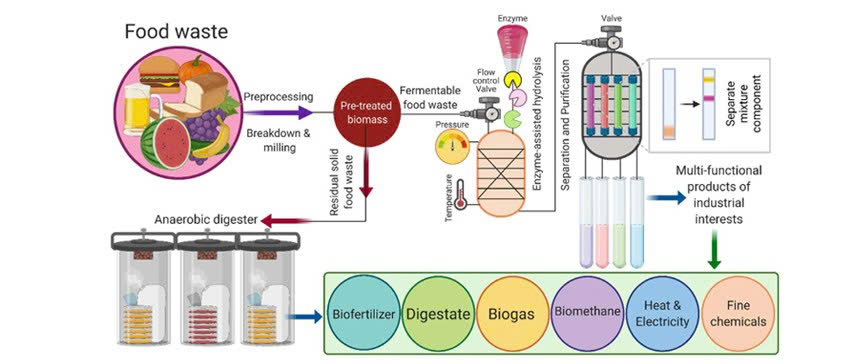

Amidst depleting fossil reserves and fluctuating oil prices, these two studies propose a paradigm shift from "waste disposal" to "waste valorization". This strategy integrates two primary pathways: (1) ReFeed—recycling waste into animal feed to substitute grains, and (2) Biotechnology—utilizing enzymes and microorganisms to transform waste into clean energy and industrial chemicals.

Extraction and (bio) conversion of food wastes into value-added materials

- Nutritional Profile: Pooled analyses from multiple trials indicate that consumption-stage food waste is highly nutritious: Mean Crude Protein is 19.2% (nearly double that of maize grain), Lipids 21.5%, and Carbohydrates 38.6%. Theoretically, one ton of dry food waste could replace an equivalent amount of maize in pig diets without detrimental effects on meat quality.

- Safety Technologies: To overcome biosecurity barriers (such as bacteria and viruses), modern treatment technologies have been developed.

+ Wet-based: Heat sterilization (e.g. 100oC for 4 hours) eliminates pathogens, creating liquid feed suitable for nearby farms.

+ Dry-based: Combines sterilization with dehydration (e.g. fluidized bed or drum drying) to produce low-moisture feed (80-95% dry matter), which is easy to transport over long distances and store for extended periods.

+ Ensiling/Fermentation: Uses lactic acid bacteria and yeast to ferment waste, stabilizing nutrients and extending shelf life up to 30 days.

In South Korea, landfilling of food waste was banned in 2005; instead, 45% of the waste is converted into animal feed through strictly controlled centralized processing facilities, and no disease outbreaks associated with this practice have been recorded since its implementation.

- The Biotechnological Strategy: Energy and Bio-based Chemicals [1]

Sufficiency et al. (2022) expand the scope to advanced biotechnological methods, particularly suitable for waste streams unfit for animal feed.

- ðIn conclusion, food waste must be recognized as a sustainable raw material resource rather than an environmental burden. A flexible combination of recycling into animal feed (for safe, nutrient-rich waste) and biotechnological treatment (for mixed waste to recover energy) is the optimal direction. Realizing this requires a shift in management policies, investment in advanced enzymatic technologies, and the establishment of rigorous safety control protocols.

References

1. Sufficiency, E., Qamar, S. A., Ferreira, L. F. R., Franco, M., Iqbal, H. M., & Bilal, M. (2022). Emerging biotechnological strategies for food waste management: A green leap towards achieving high-value products and environmental abatement. Energy Nexus, 6, 100077.

2. Dou, Z., Toth, J. D., & Westendorf, M. L. (2018). Food waste for livestock feeding: Feasibility, safety, and sustainability implications. Global food security, 17, 154-161.